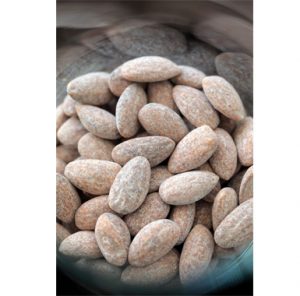

1- Selection and storage of almonds:

The first step that will be decisive for the quality of the final dragee is of course that of the selection of almonds.Present on this market for more than 60 years, we master the sourcing of almonds, vital asset in a booming global demand context.Almonds mainly from Sicily, Spain and Provence are then stored in a cold room.

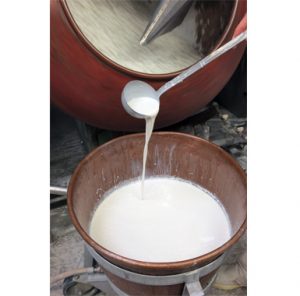

2- Gum Arabic Cover:

During the first stage, almond or chocolate (constituting the core of the dragee) are mixed in a rotating turbine with a mixture of gum arabic (acacia) and sugar (each turbine can contain nearly 250kg dragees). By depositing a protective film on the almond, gum arabic smoothes the dragée and fix moisture and fat inside it.

3- Coating:

Then comes the very delicate coating phase. Through a complex mechanism, sugar heaten to more than 100 ° is sprayed onto the cores in the form of multiple drops. The operation lasts more than three hours : time to get a sugar shell of the desired thickness before the final stage.

4- Colouring:

To color the dragee is added sugar syrup. The varnish aspect is provided by a food varnish. All the steps to make a dragee last 72 hours. The more sugar layers, the longer the process lasts.

5 Sorting:

Four to five person daily sort by hand : they look for the slightest imperfection. Little damaged, improper size or shape, uneven color … the slightest default dragee is departed. Less than 1% of production is eliminated. Due to its premium positioning and title of Living Heritage Company, the company wants to move towards the most perfect possible products.

6. Packaging and weighing:

Conditioning is done by hand when others have assigned this task to the machine.